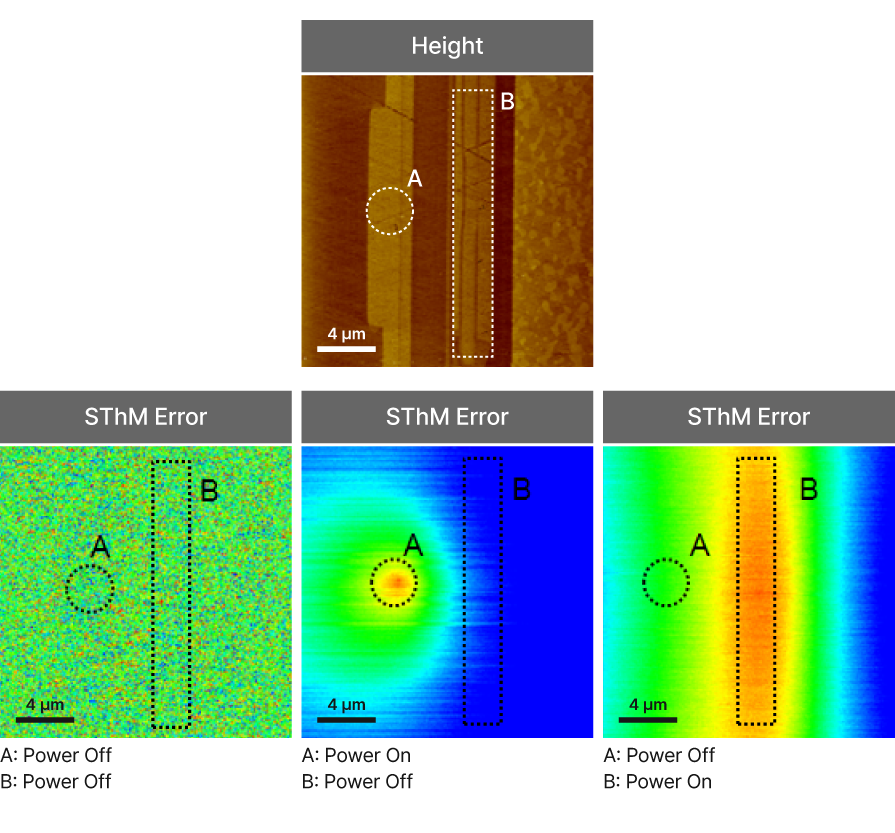

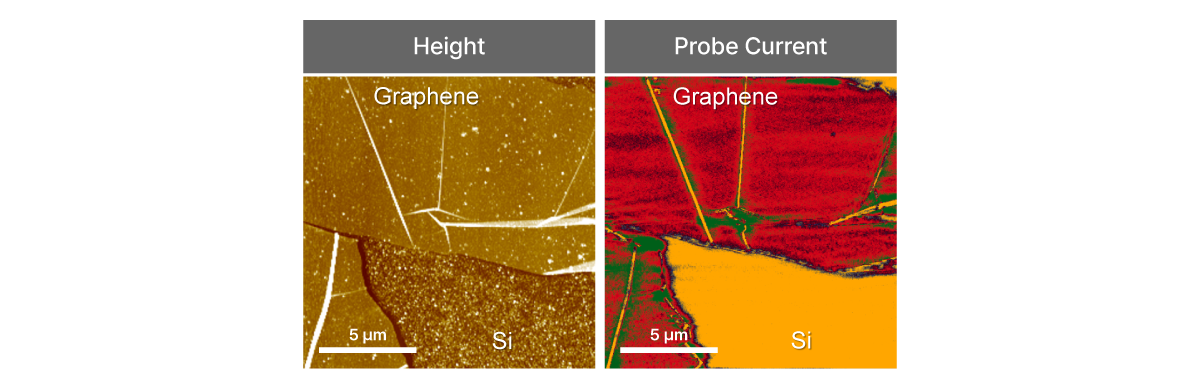

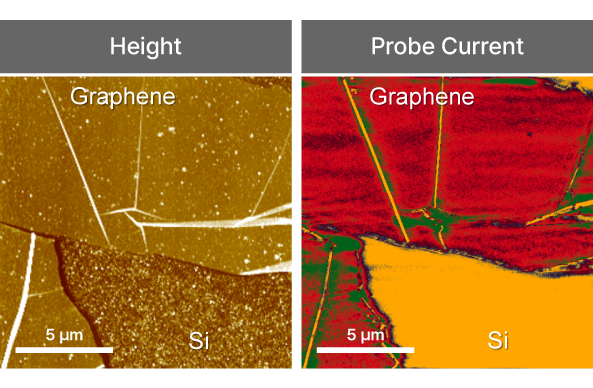

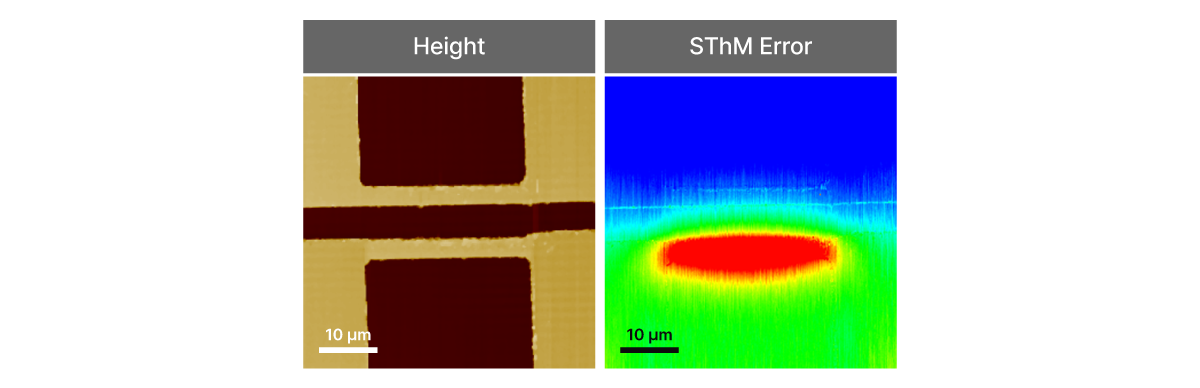

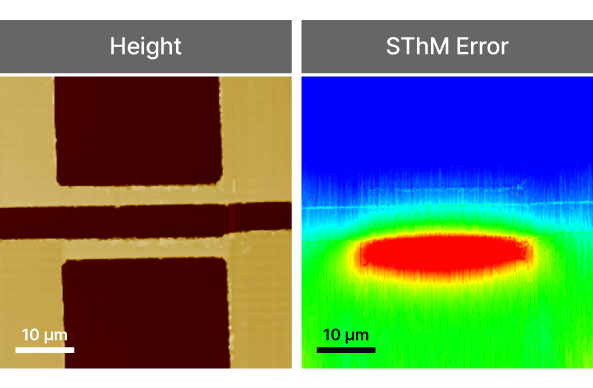

Scanning Thermal Microscopy

SThM

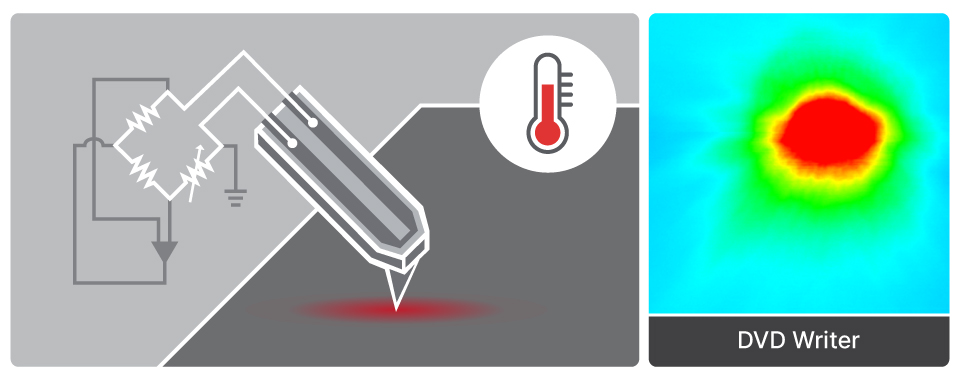

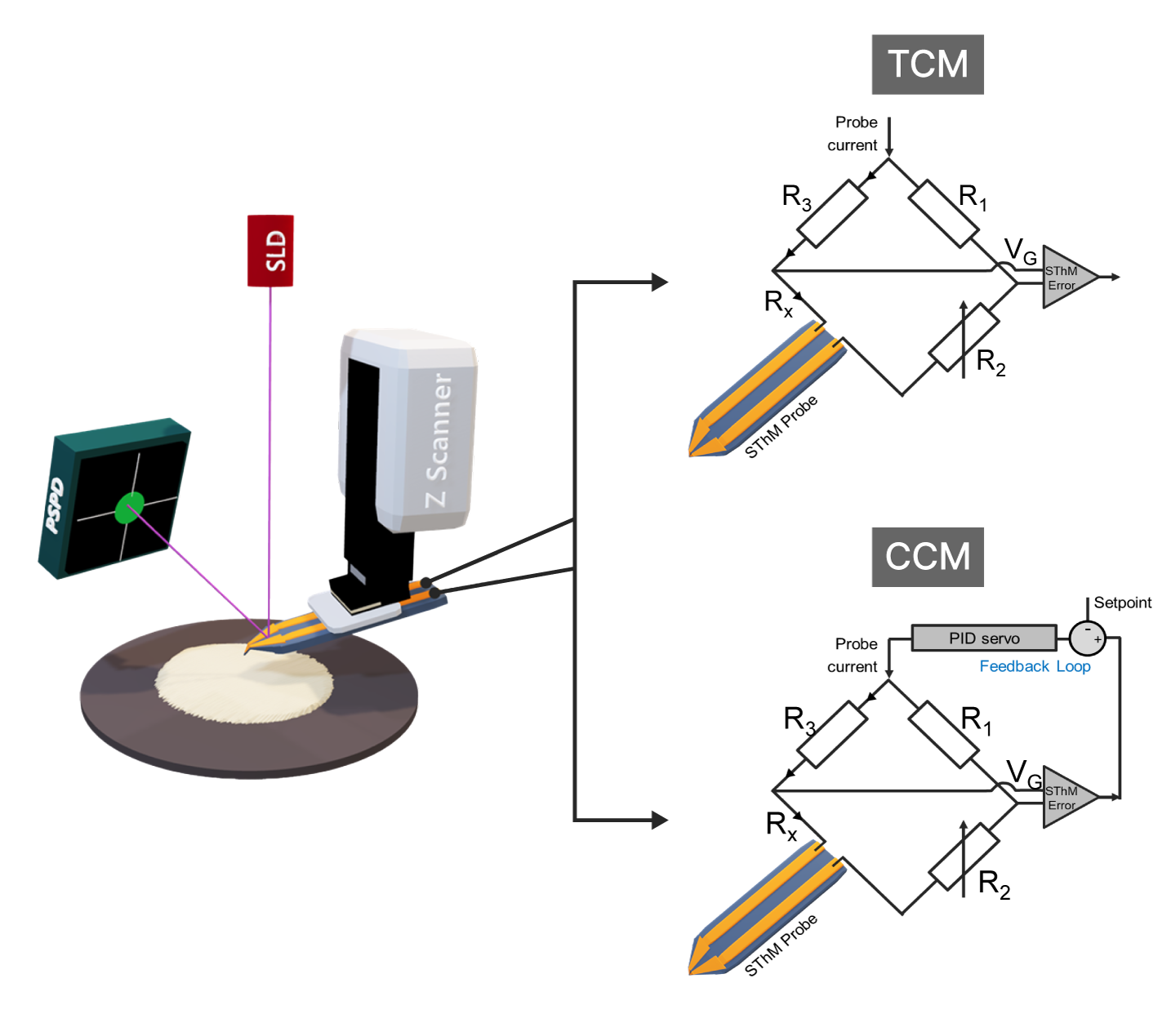

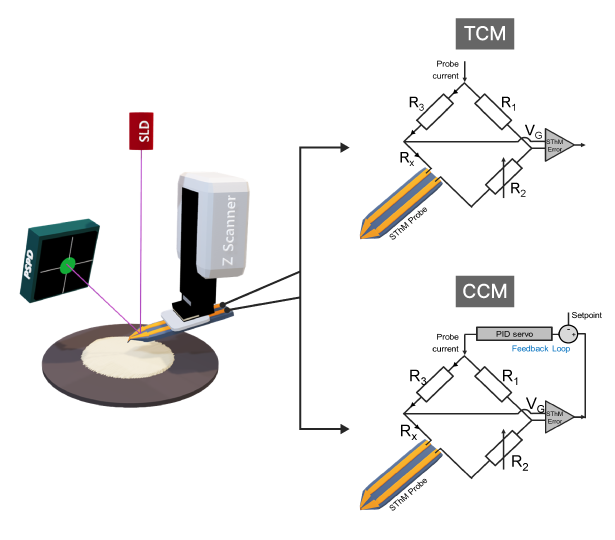

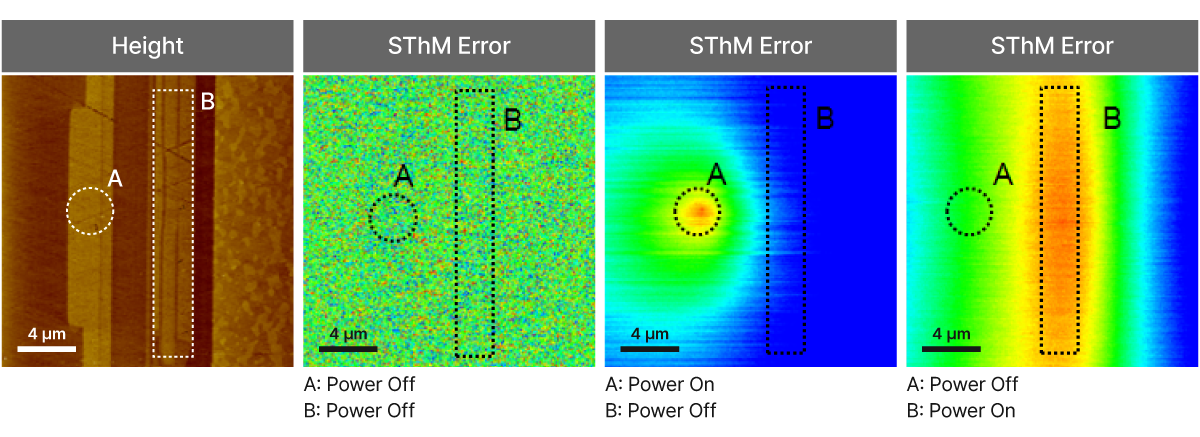

Thermal conductivity and temperature distribution imaging at the nanoscale using a nanothermal probe