Electrochemical AFM

EC-AFM

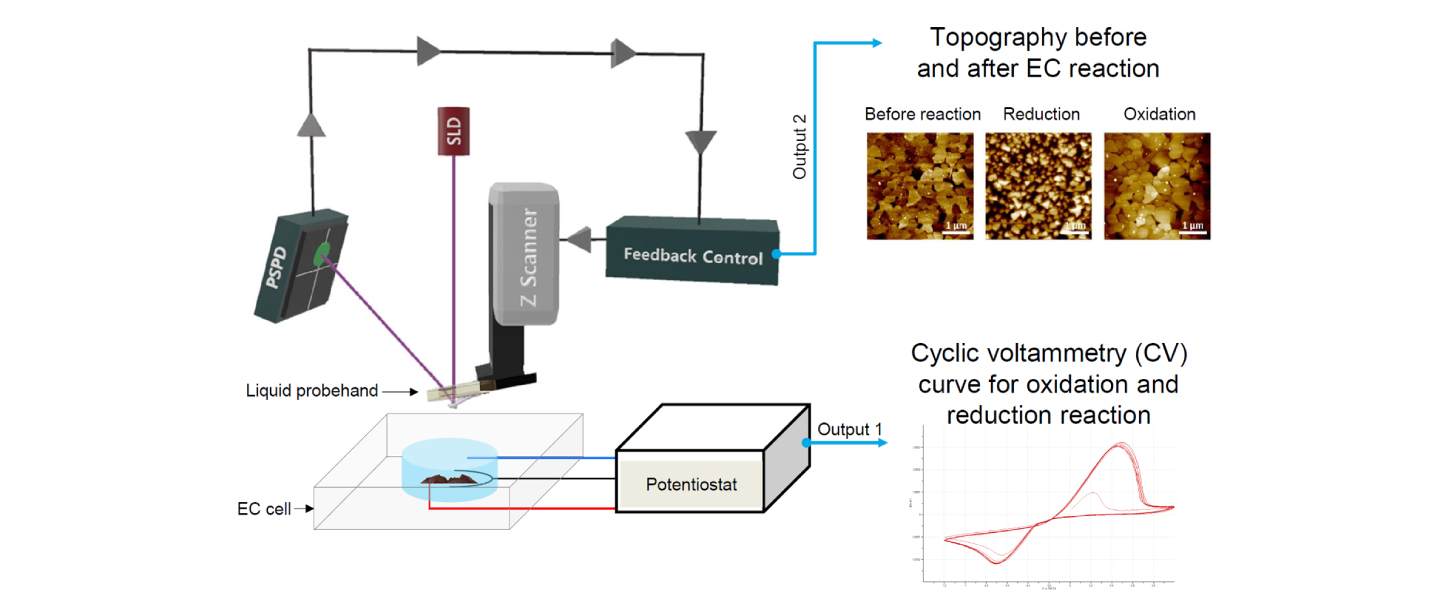

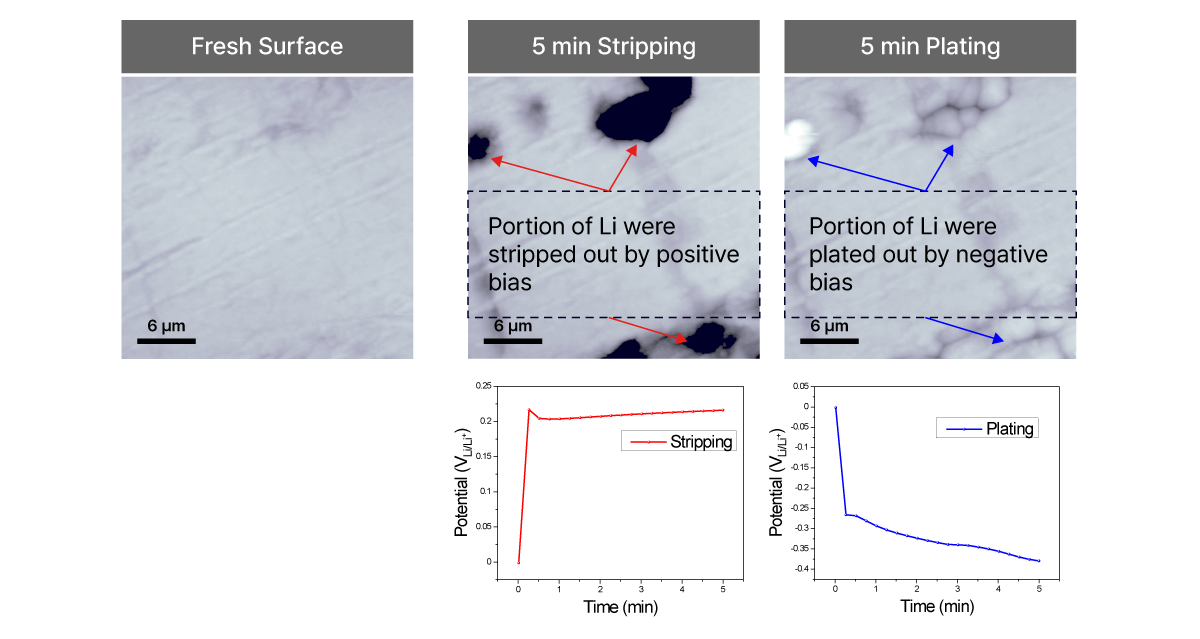

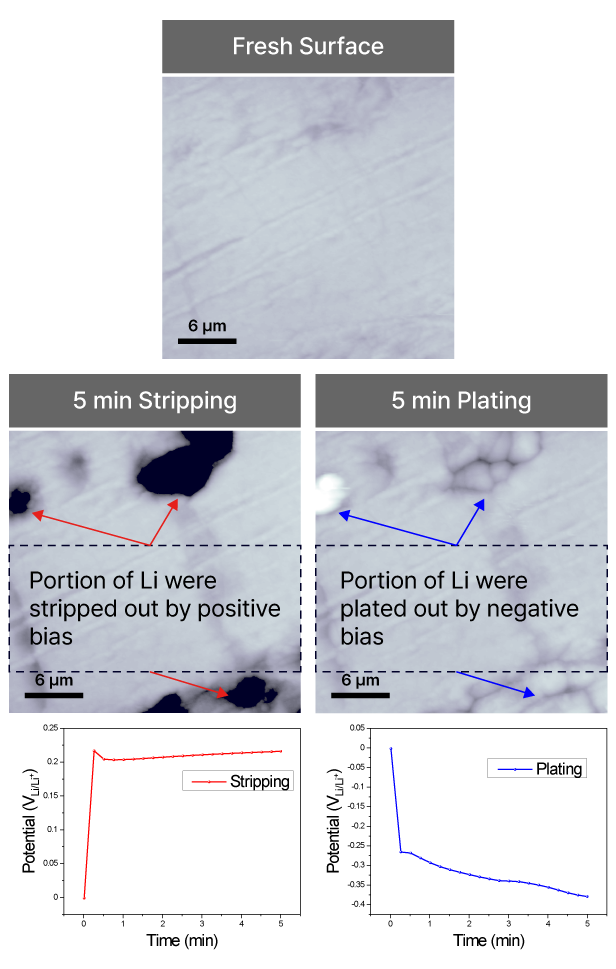

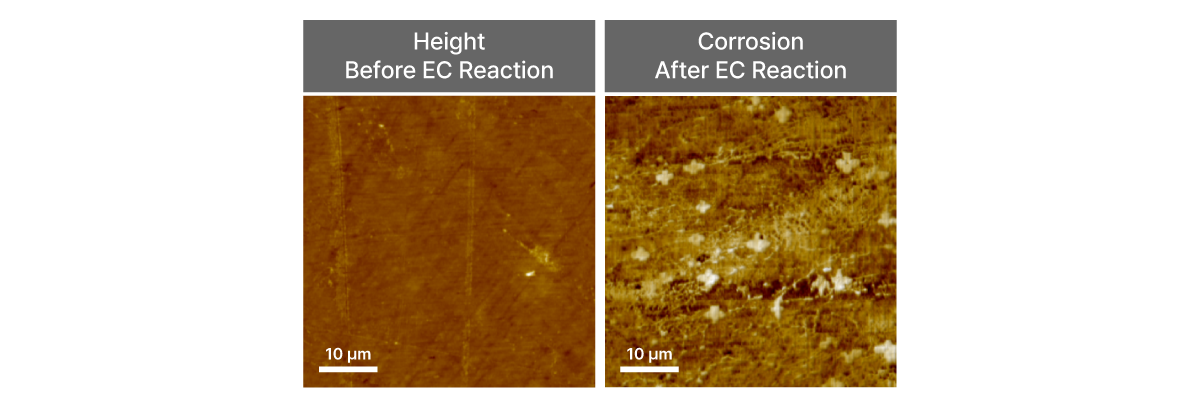

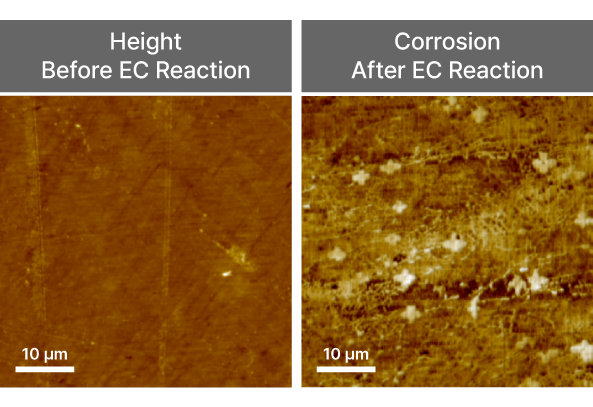

In-situ imaging of electrochemical reactions in liquid environments