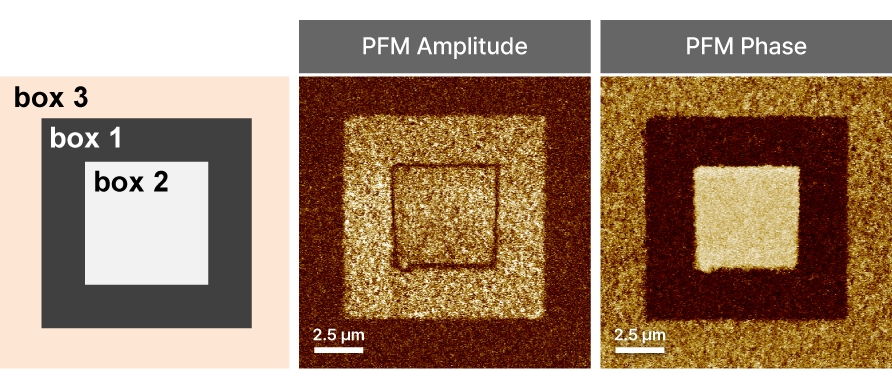

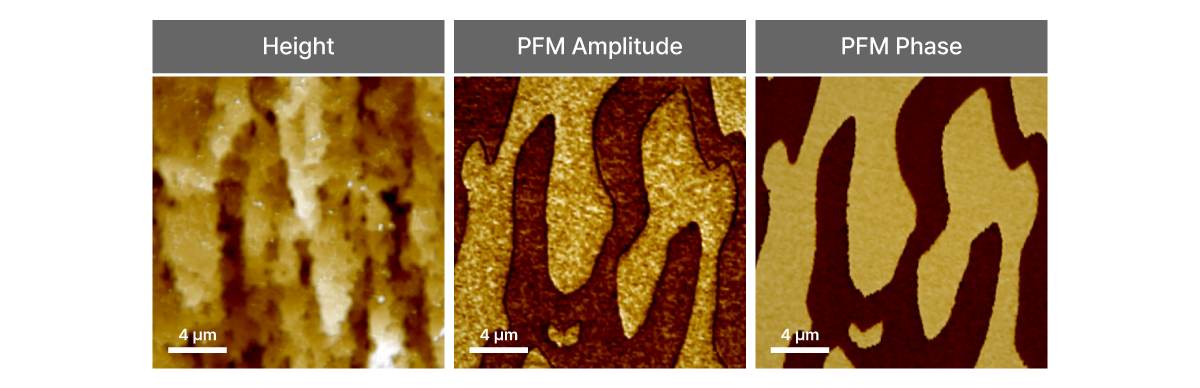

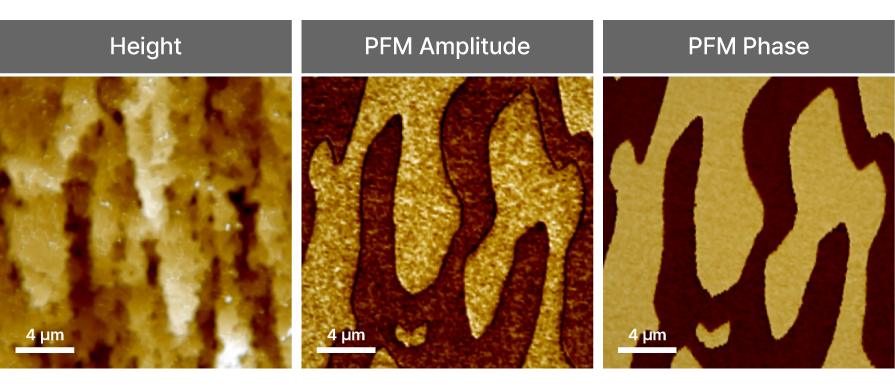

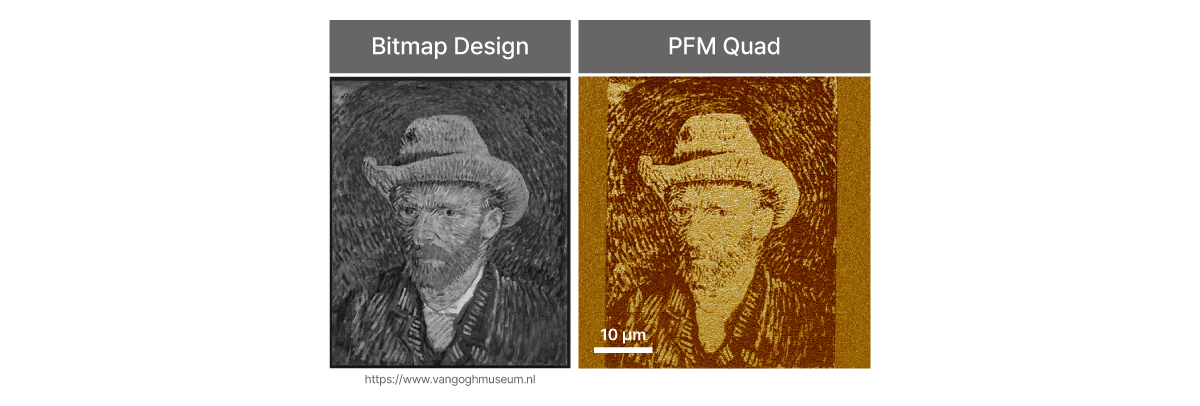

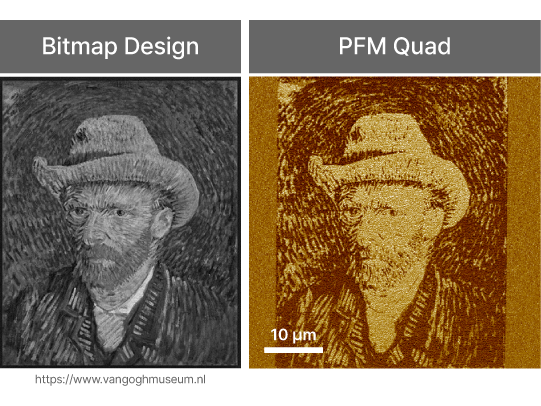

Piezoreponse Force Microscopy

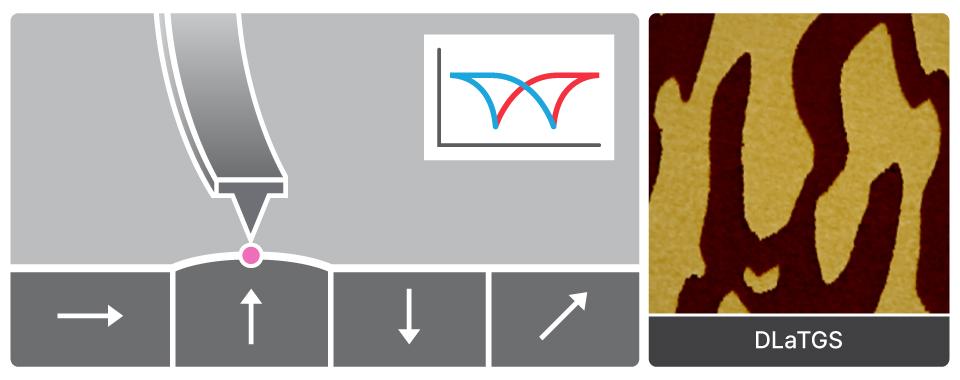

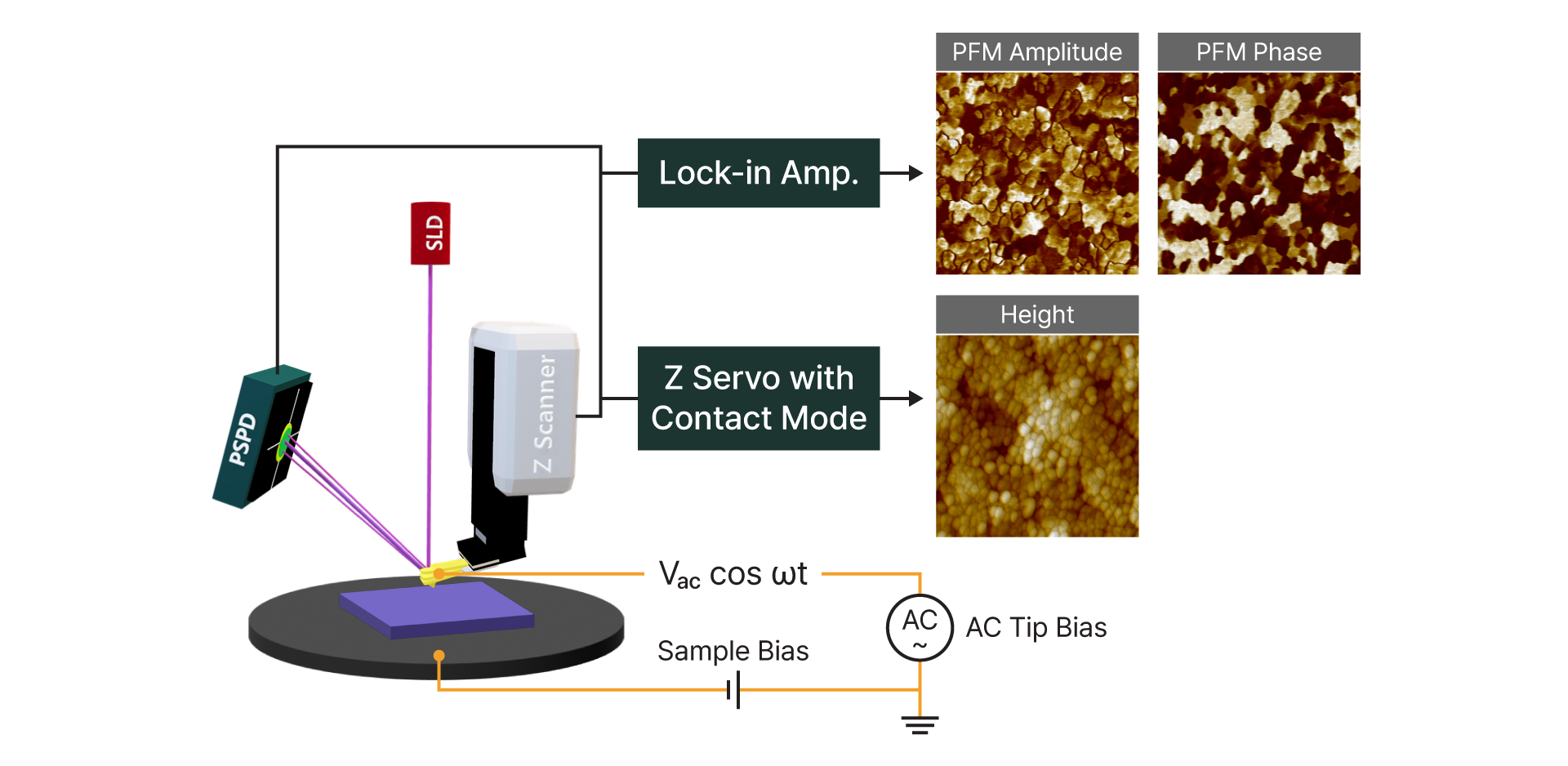

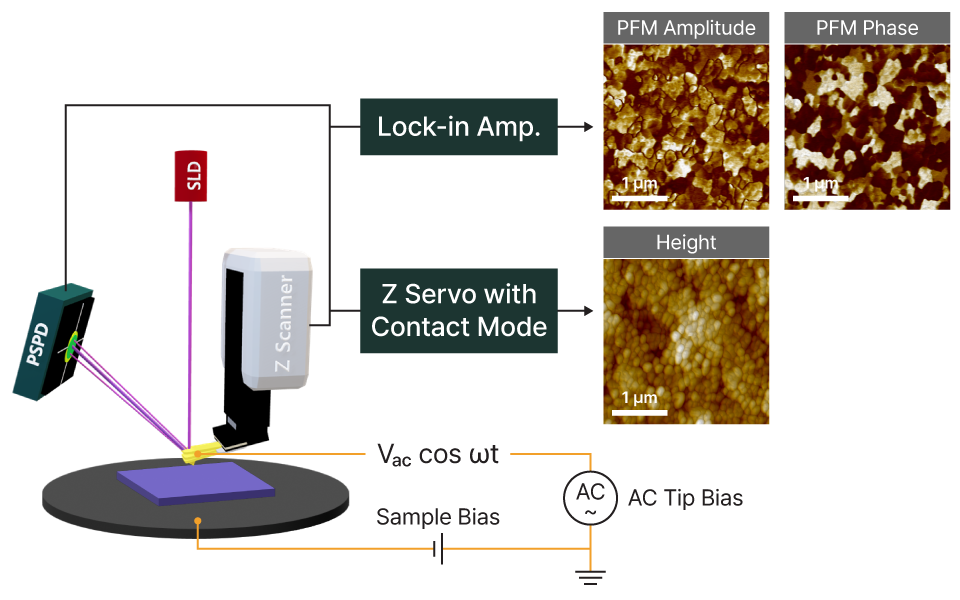

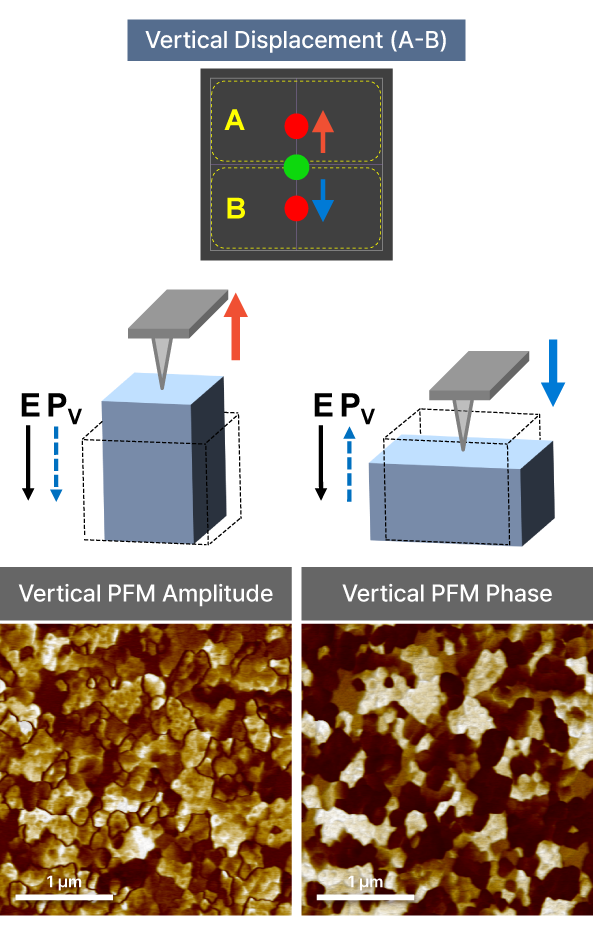

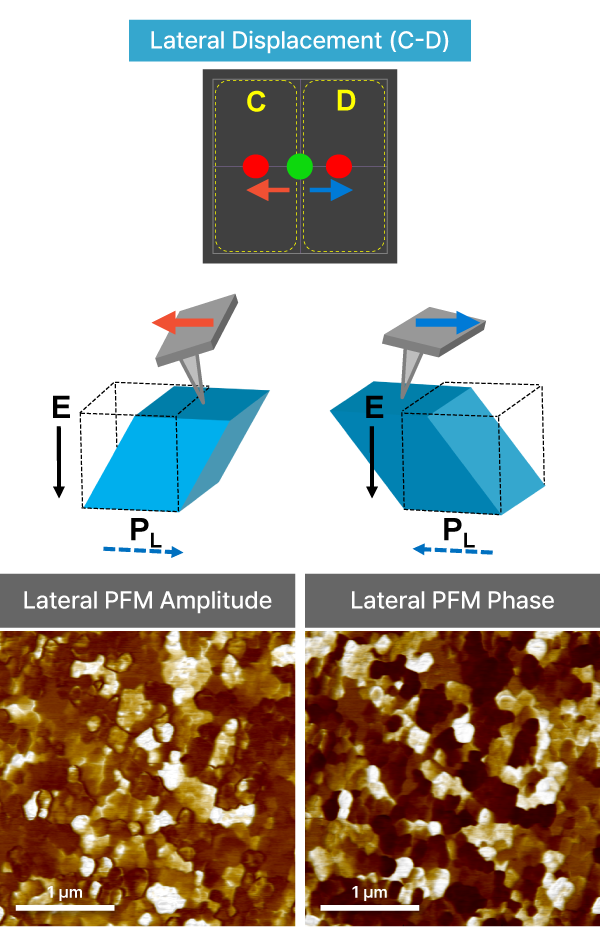

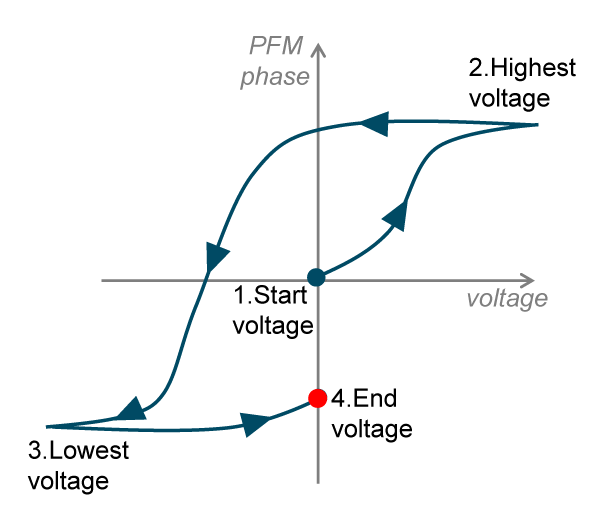

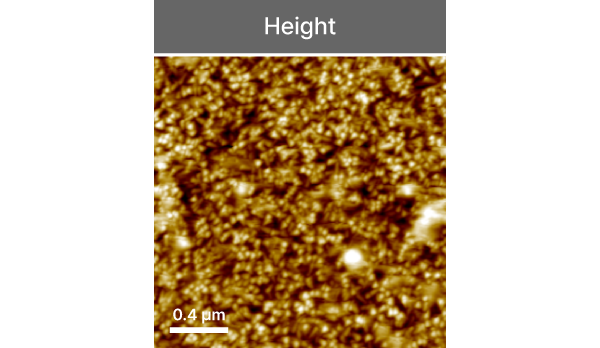

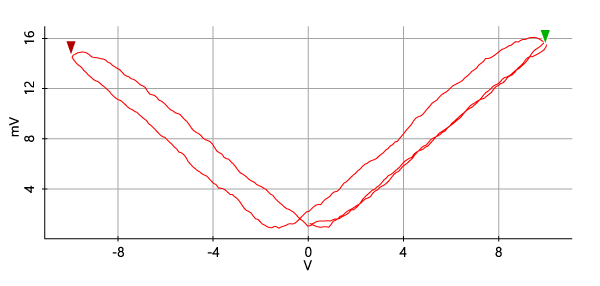

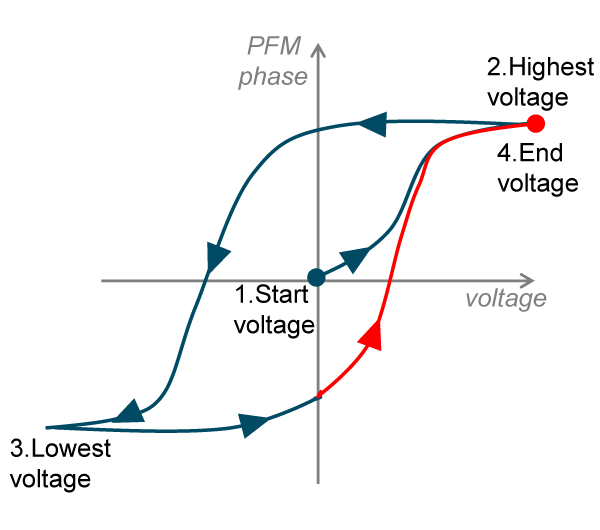

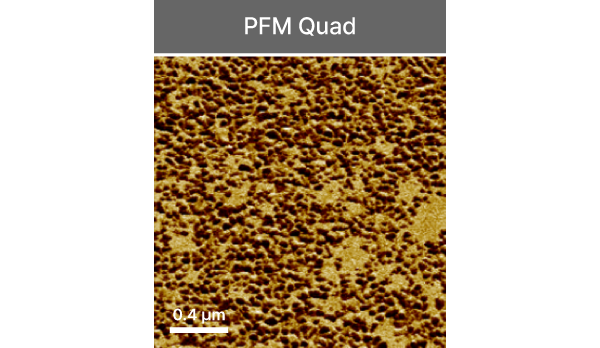

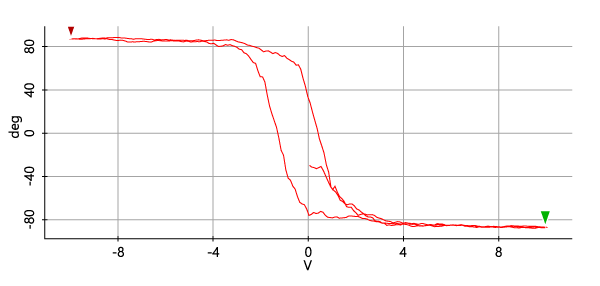

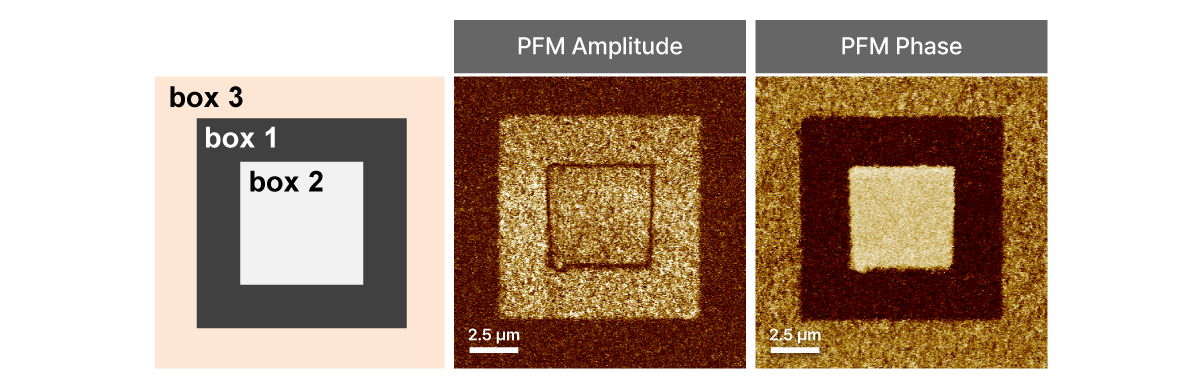

PFM

Nanoscale ferroelectric and piezoelectric domain imaging through electromechanical coupling detection