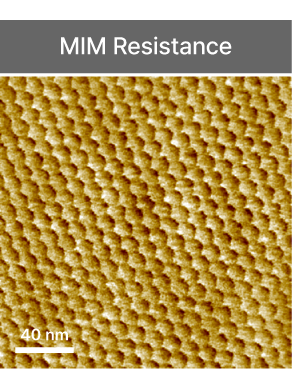

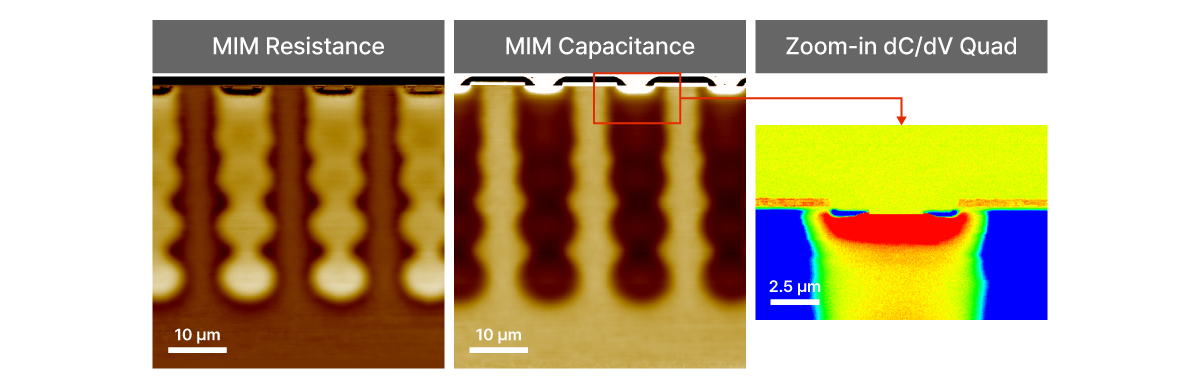

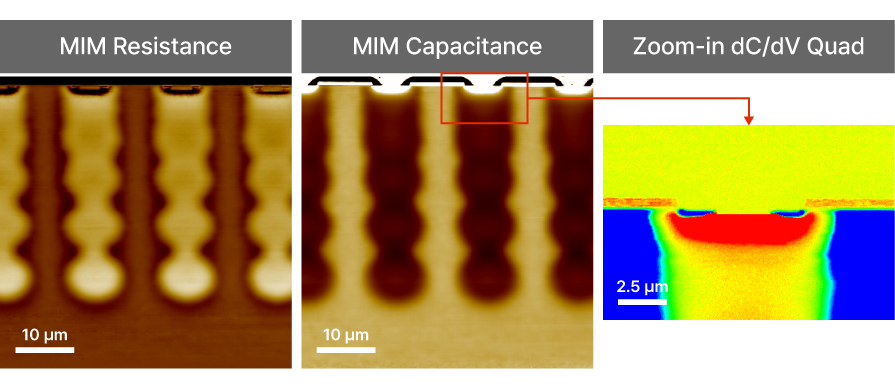

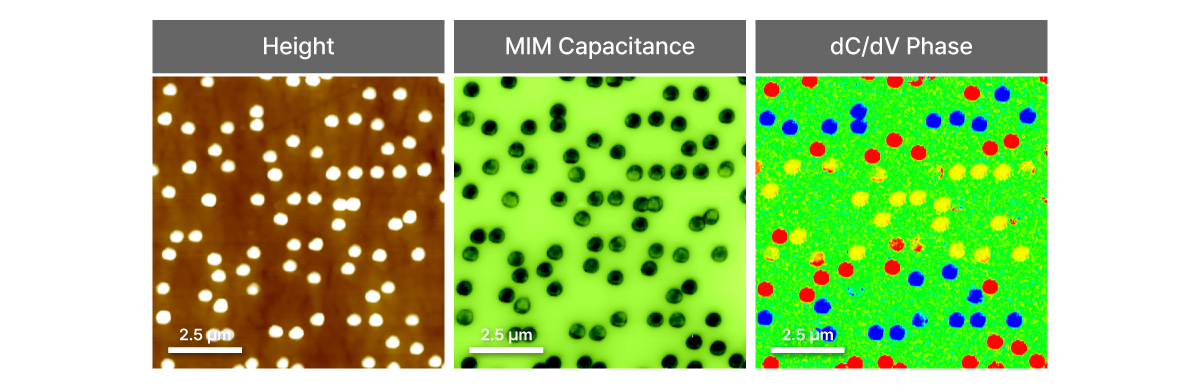

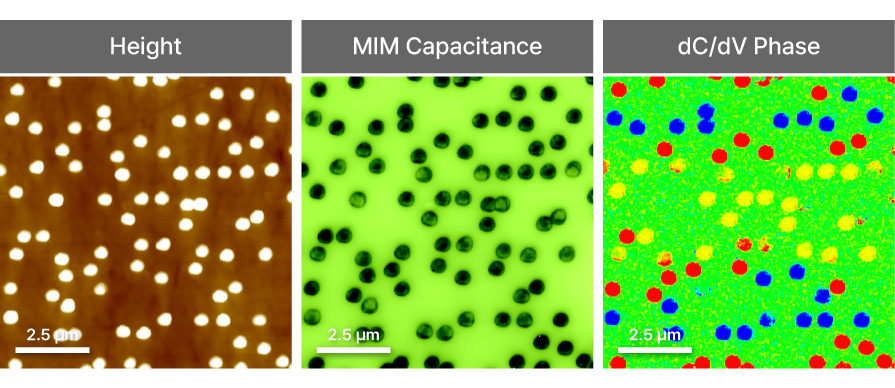

Microwave Impedance Microscopy

MIM

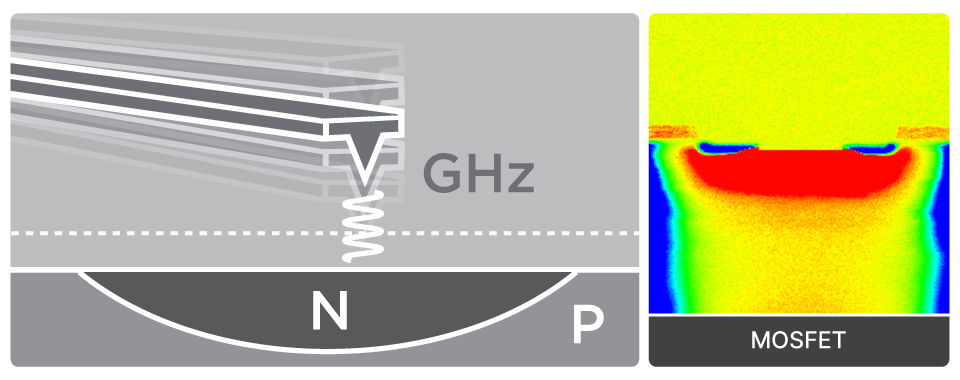

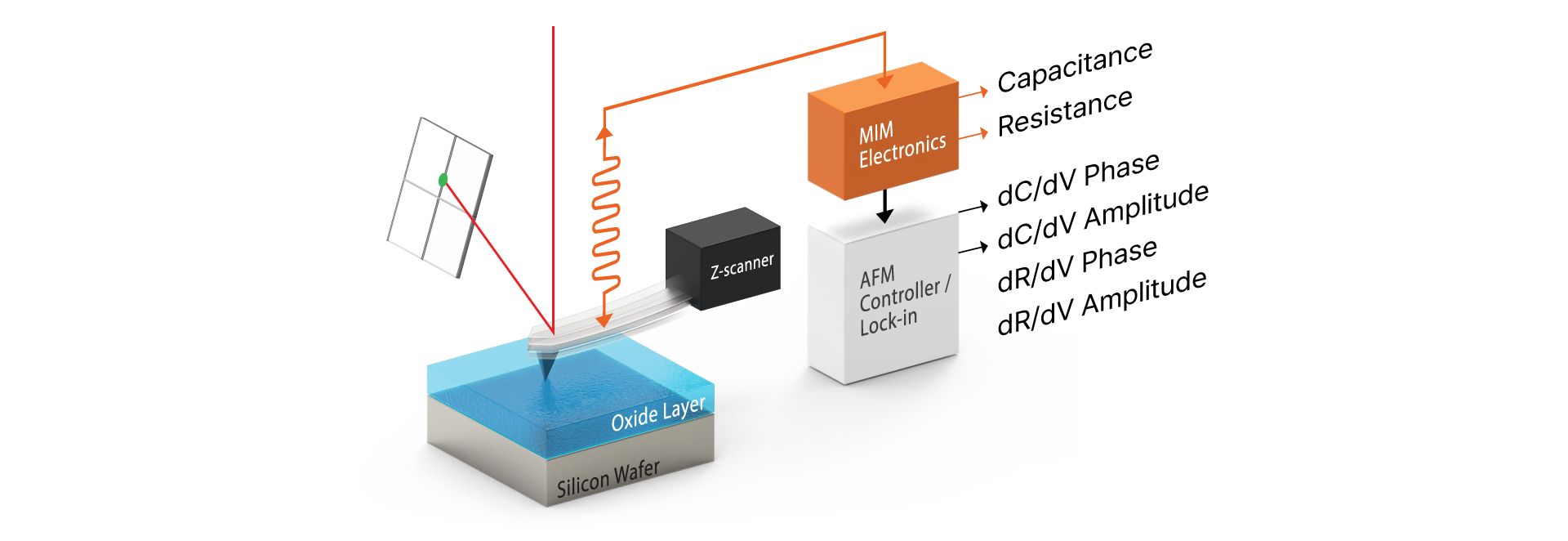

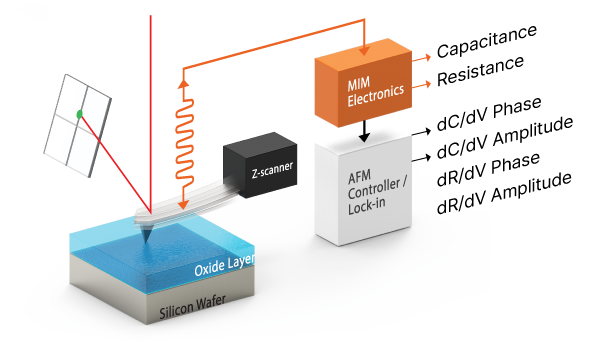

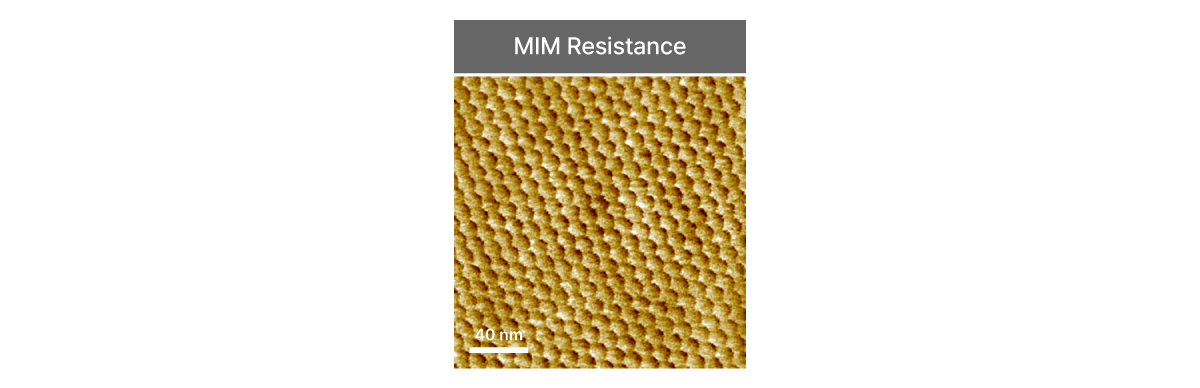

Nanoscale electrical property mapping based on capacitance and conductivity changes