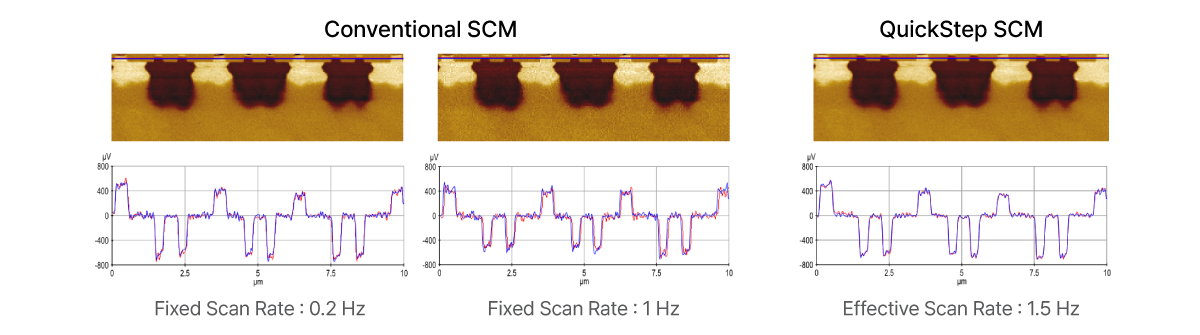

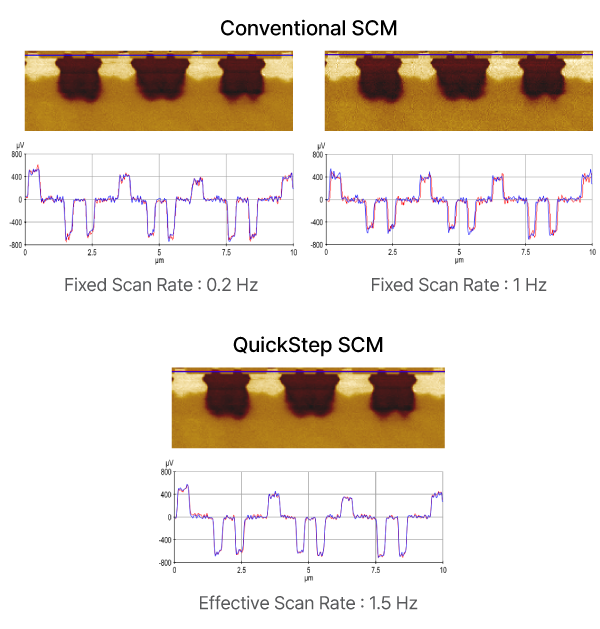

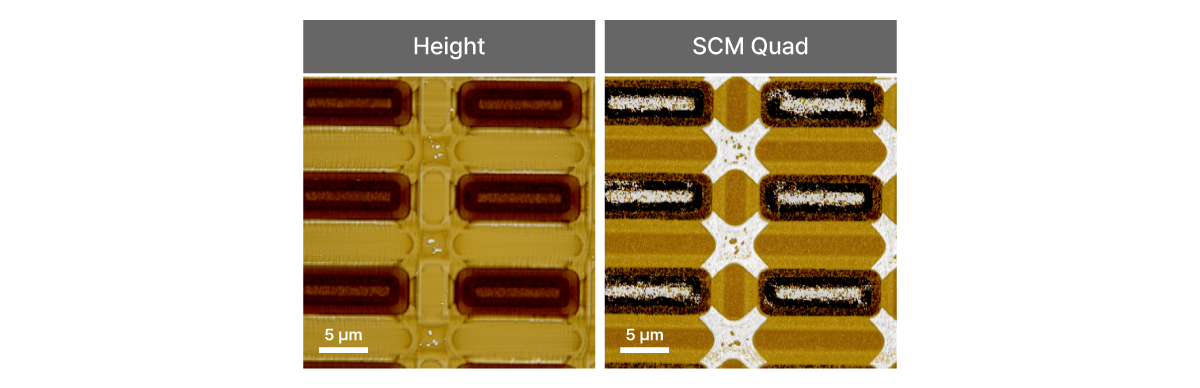

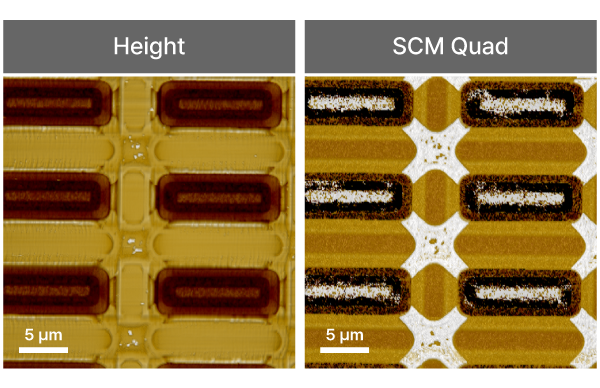

Scanning Capacitance Microscopy

SCM

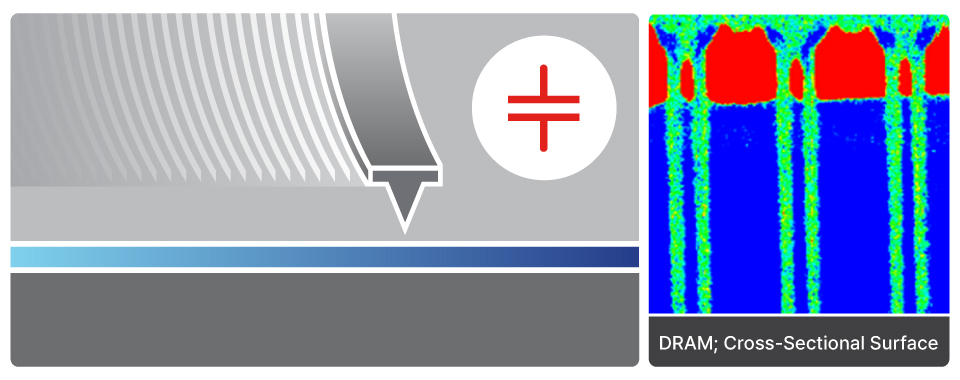

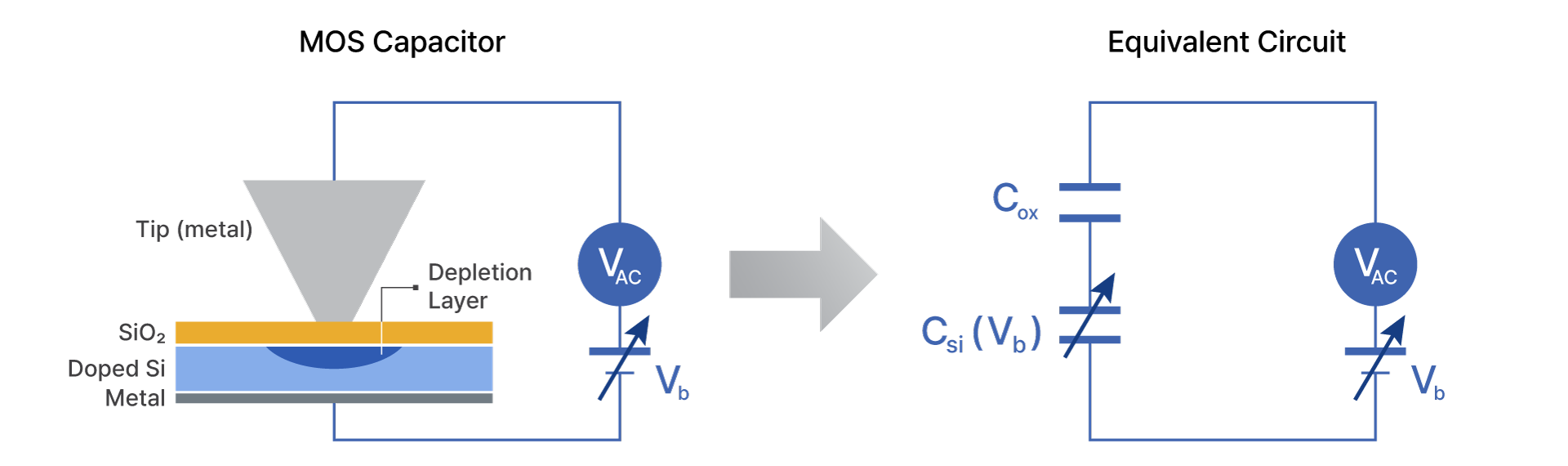

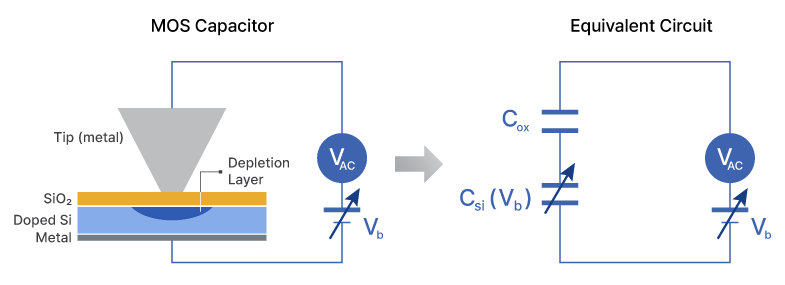

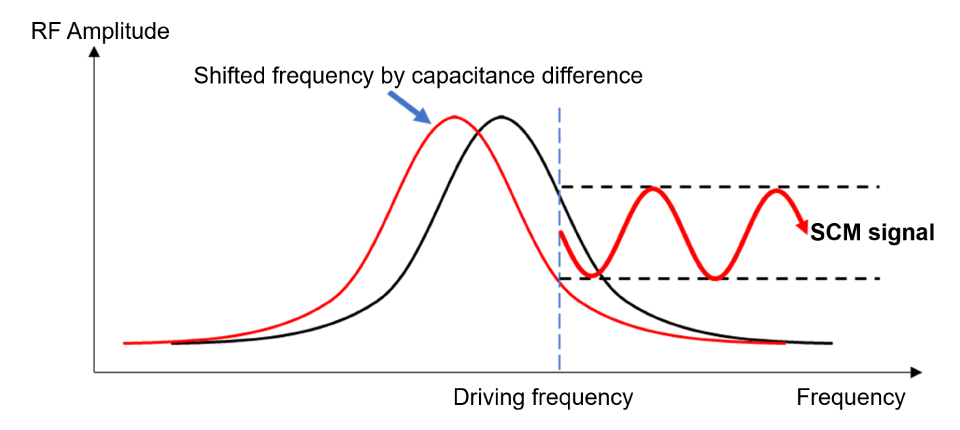

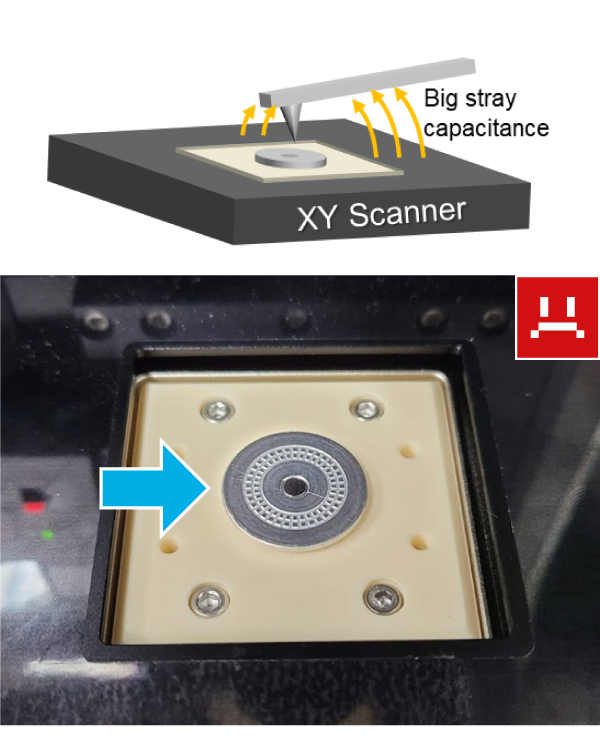

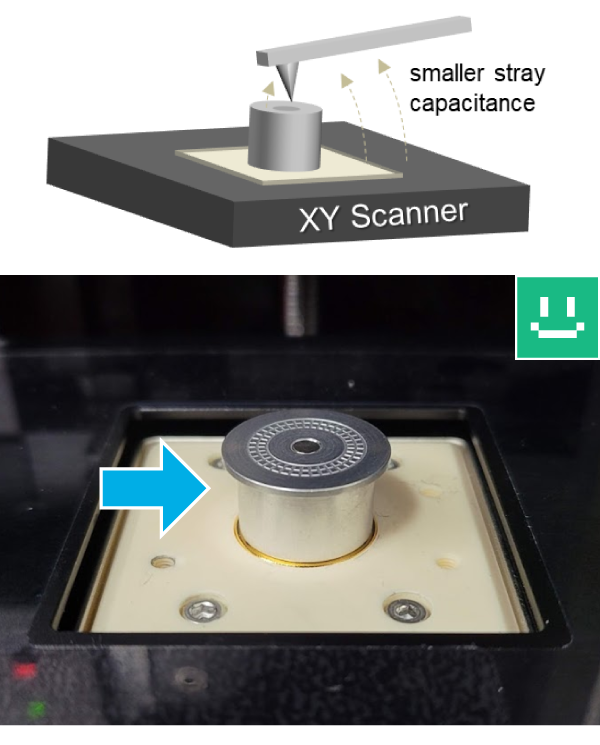

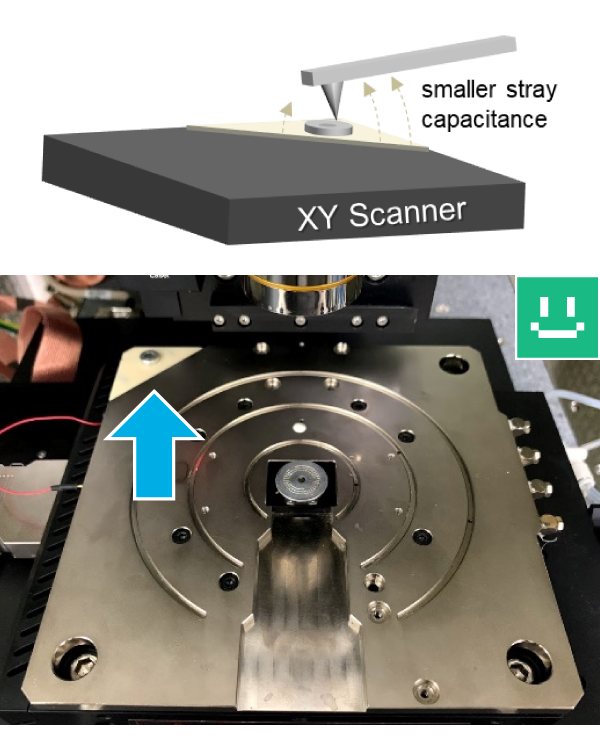

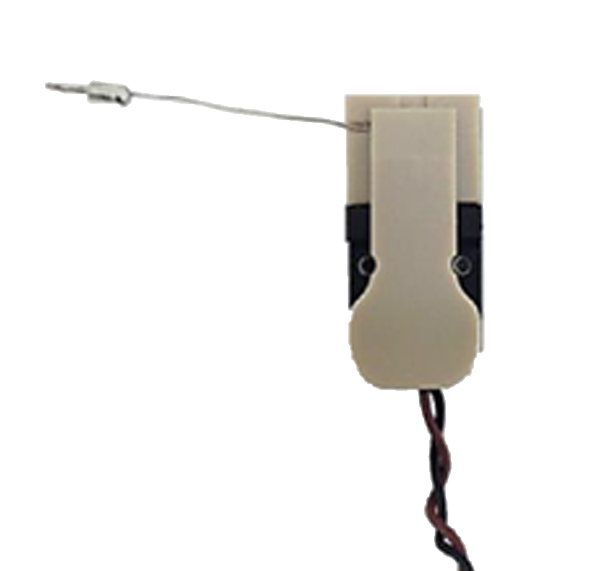

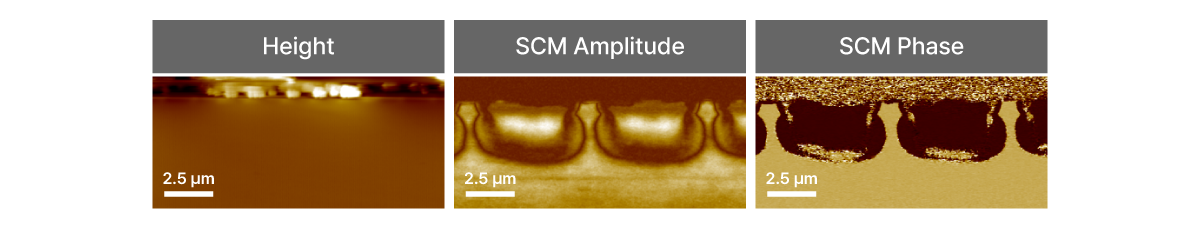

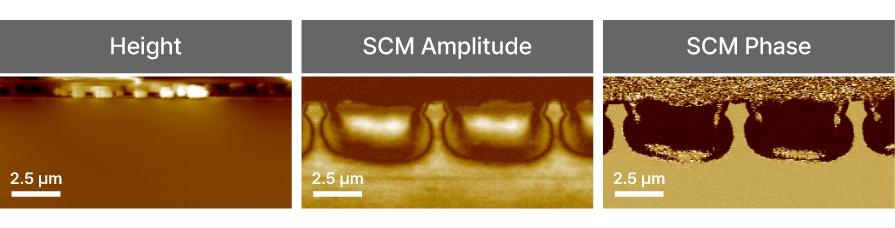

Nanoscale semiconductor doping and carrier profiling by detecting capacitance variations between the AFM tip and sample under AC bias